FUSED REFINING FLUXES

The Refinal range of environmentally-friendly fused granular refining agents offer an excellent alternative to chlorine fluxing in the furnace to remove alkali metals and inclusions.

The Refinal range is supplied to smelters worldwide and a series of development programmes have resulted in formulations which offer enhanced performance at lower cost.

Refinal 350

This is based on minimum 35% magnesium chloride, a highly efficient remover of alkali metals and oxides from molten aluminium.

Refinal 352XF

This is also based on minimum 35% magnesium chloride, but with the addition of fluoride, has further enhanced performance and increased efficiency by up to 25%.

Refinal 565XF

This is based on the partial substitution of the potassium chloride content with up to 30% sodium chloride, making it a cost-effective remover of alkali metals and oxides from molten aluminium.

Refinal HAL F7

A key component of this flux is the addition of a high activity fluoride, which enhances performance and increases efficiency. Crucially, while existing fluxes can cope with removing particles above 15 microns in size, this flux can remove particles below 12 microns. These include very fine oxides commonly found in light scrap used in remelts.

Market leader

ACT has established Refinal as a market leader and the product has excellent synergy with a rotary flux injector (RFI).

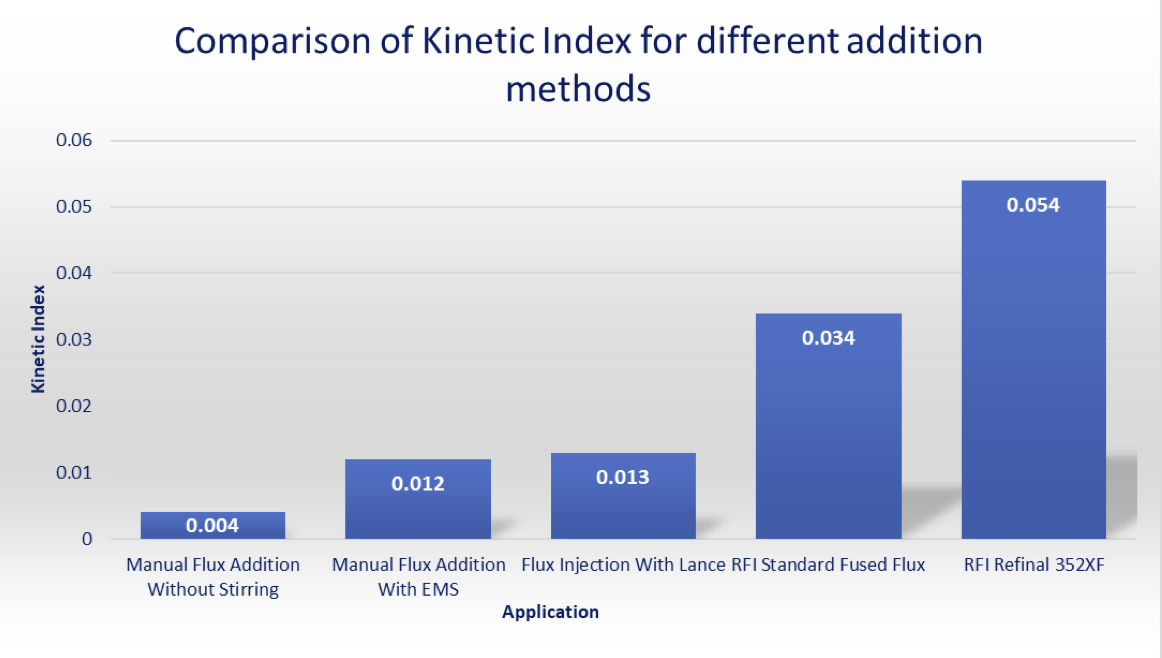

The RFI, used with Refinal fluxes, provides the ideal application system for impeller furnace stirring and fluxing. Reaction kinetics reveals that the rate of removal of alkalis using different addition methods can be compared by the rate removal constant (k). The k value is much higher and, therefore, alkali removal is greater when using the RFI and the k value is particularly high when using Refinal with added fluoride.

Studies by Hydro Aluminium Rolled Products have also shown that flux treatments with the RFI impeller system generate 50-70% less dross than alternate flux addition methods or with chlorine gas, a huge benefit for casthouses.

Graph: The effect of flux mixing method on kinetic index k

Get in touch if you’d like more information about any of our Refinal products, we’ll be happy to discuss your requirements.